Business

How Cloud-Based Manufacturing Solutions Are Shaping the Future

Table of Contents

- Flexibility and Scalability

- Real-Time Data Access and Analytics

- Enhanced Collaboration

- Cost Reduction

- Challenges and Considerations

- Future Outlook

Key Takeaways

- Cloud manufacturing provides adaptability and scalability, enabling manufacturers to quickly align with shifting consumer and market demands while minimizing overhead.

- Real-time data access and robust analytical capabilities enhance operational efficiency, facilitate proactive decision-making, and lay the groundwork for predictive maintenance and innovation.

- Cloud-driven collaboration streamlines communication and information sharing across global supply chains, fostering transparency and synchronization from suppliers to end customers.

- Shifting to cloud-based solutions significantly lowers costs by reducing the need for capital-intensive infrastructure, thereby freeing up resources for growth and technological advancement.

- Challenges such as data security, regulatory compliance, and integrating older legacy systems require thoughtful planning, advanced security protocols, and effective organizational change management to achieve seamless cloud adoption.

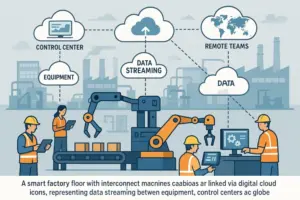

Cloud-based manufacturing solutions are transforming the industry by enabling greater efficiency, agility, and global collaboration. Through platforms such as cloud based manufacturing software, companies can swiftly adapt to changing market demands and supply chain disruptions without the high costs associated with traditional IT infrastructure. This shift is enhancing supply chain coordination, streamlining production, and fostering innovation throughout the entire design-to-delivery process.

Manufacturers embracing cloud technologies gain competitive advantages through real-time data access, automation, and simplified IT management. Cloud-based platforms also enhance collaboration across distributed teams and partners. As digital transformation accelerates globally, cloud-based manufacturing software is proving essential for companies seeking long-term resilience and peak operational performance.

Flexibility and Scalability

Modern manufacturing requires adaptability due to shifting consumer demands and market disruptions. Cloud-based solutions provide manufacturers with the flexibility to scale their operations, launch new products, and enter new markets without the limitations of traditional systems. These platforms enable real-time adjustments to production and resource allocation, helping to avoid overproduction and reduce costs. For instance, companies can quickly scale up for seasonal products across locations. Unlike rigid legacy systems, cloud platforms provide fast and cost-effective scalability.

Real-Time Data Access and Analytics

Cloud-based manufacturing systems offer immediate access to critical operational data, converting it into actionable insights via intuitive dashboards. These real-time analytics enable manufacturers to monitor processes and respond swiftly to any inefficiencies continuously. A key benefit is predictive maintenance, which prevents costly equipment failures by anticipating issues before they occur. This proactive approach reduces downtime and extends machine life, offering cost savings and a competitive advantage. Ultimately, real-time insights support better decision-making and more sustainable operations.

Enhanced Collaboration

Cloud platforms enhance global teamwork by providing centralized access to shared data, documents, and analytics, regardless of location. This level of connectivity streamlines communication among suppliers, engineers, assemblers, and customers. By eliminating delays associated with traditional tools and time zone differences, cloud systems create a more agile and cohesive collaboration environment.

Streamlining Multi-Tier Supply Chains

Cloud tools establish a “single source of truth,” ensuring all supply chain stakeholders work from consistent, up-to-date information. They improve coordination by making changes—like revisions to materials or quality standards—immediately visible to all parties. This transparency helps prevent miscommunication, minimizes delays, and strengthens operational efficiency across complex, layered supply chains.

Cost Reduction

Shifting to cloud-based systems significantly reduces IT expenses, replacing significant upfront investments with flexible, subscription-based models. This transition from CapEx to OpEx allows manufacturers to scale their tech resources as needed while avoiding maintenance burdens. Additional savings arise from lower energy use and reduced administrative workloads, enabling reinvestment in innovation, training, and growth.

Challenges and Considerations

Security is a significant concern, as sensitive manufacturing data is stored online, necessitating robust encryption, identity controls, and security audits. Another hurdle is integrating cloud systems with older, incompatible legacy equipment. Successful implementation requires careful planning, pilot testing, and change management efforts to upskill staff and align the organization with digital transformation goals.

Future Outlook

Cloud computing, when combined with AI, IoT, and automation, is driving the evolution of smart factories and Industry 4.0. Digital twins—virtual models of physical operations—allow for simulation and optimization before real-world deployment. With rapid growth in this space, cloud-based systems are set to redefine manufacturing by boosting agility, efficiency, and resilience. Companies that embrace this digital shift will maintain a competitive edge in the global market.